Not applicable to Net 30 POs

FarmBot Inc

Series A Investment Round

Reading time: 22 minutes

Executive Summary

As the population rises, resources dwindle, and the effects of climate change worsen, our need to address the global food crisis is urgent. How we come together to feed everyone healthy and sustainable food is a story that has yet to be written.

FarmBot, Inc. and our burgeoning community is founded on the belief that a more open food system is a better one, and that we will all benefit if we freely share the tools, methodologies, and wisdom needed to grow food. We believe that we can accomplish much more by working together towards common goals. The solutions to the challenges of the global food crisis will not be found by any one individual or company, but by a whole movement of inspired and empowered people.

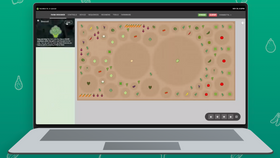

FarmBot is a 100% open-source hardware, software, and data platform designed for small to medium-scale automated precision food production. The hardware is similar to a large 3D printer, in that it moves around in the X, Y, and Z directions, all controlled by a computer. FarmBot deposits seeds in the ground, waters them, detects and removes weeds, and monitors the garden using onboard sensors. Current devices tend to a garden up to 3m wide and 6m in length. The user controls and configures FarmBot using a powerful web-based interface, similar to a video game. Users simply drag and drop plants into the virtual map, and FarmBot can do the rest.

After three years of R&D, FarmBot Genesis was launched in July of 2016 with a self-hosted crowdfunding campaign. In just two months, we pre-sold over $1,000,000 worth of FarmBot kits and inspired organic sharing of our ideas all across the globe. To date, we have shipped over 500 FarmBot kits worldwide, pre-sold an additional 150 more, and seen over 150 million views of our videos across the web. Our community is growing at an astounding pace, with hundreds of educators, students, DIY food enthusiasts, agricultural companies, and researchers diving into this technology with us.

Moving forward, we are seeking to raise $3M to meet specific growth and technical development goals through the middle of 2019, including:

- Expanding our sales and marketing, specifically in the educational vertical and international markets

- Developing official FarmBot curriculum in partnership with select institutions

- Funding the production of v1.4 devices; building inventory

- Bringing “FarmBot Express,” (a lower-cost, simplified device) to market

- Expanding our software team by 5-10 people through 2018

- Hiring administrative staff to free technical and founding members to focus on the core mission

- Investing in the global data set that powers FarmBots (OpenFarm.cc)

- For more information, please contact rory@farmbot.io.

About the Company

FarmBot began in September of 2013 when Rory Aronson published a white paper outlining the creation of an automated farming device. In March of 2014 Aronson began working on the project full-time through the support of a $125,000 grant from the Shuttleworth Foundation. Soon thereafter he was joined by co-founders Rick Carlino and Tim Evers, who now serve as lead software and firmware developers at FarmBot, respectively. In April of 2016, FarmBot, Inc was established as a California Benefit Corporation registered in San Luis Obispo, CA.

FarmBot began a crowdfunding campaign for its debut product, FarmBot Genesis, in July of 2016. The campaign garnered over $800,000 in pre-orders and over one million dollars in revenue within the first year. It generated a storm of media interest across the internet and print, as well as attention from research organizations such as NASA, prestigious universities such as Virginia Tech, nonprofits, and everyday DIYers.

FarmBot is uniquely positioned as the first company to sell a functioning, general purpose gardening machine. It has an active community of devoted followers and for many, is the first product that comes to mind for garden automation. This reputation is due to FarmBot’s quick entry to market and an iterative development cycle that ships results quickly to customers.

The company has now manufactured and shipped two batches of FarmBot kits to a global customer base and is actively selling more to early adopters. FarmBot employs four full-time employees and five contractors on an as-needed basis.

Corporate Structure

FarmBot Inc is a California Benefit Corporation founded in San Luis Obispo

Coded into our bylaws are the following specific benefit purposes

Openly share our products

Our company is founded on the belief that a more open food system is a better one. The following aspects of our products will be openly shared at the time the product is publicly released:

- Hardware designs shall be released in accordance with the Open Source Hardware Association’s definition of open source hardware.

- Software source code shall be released under a permissive license approved by the Open Source Initiative.

- Documentation shall be released under a license conforming to the definition of “open” put forth by the Open Knowledge Foundation.

Openly share our business

We believe that business is a powerful agent for change, and like our products, it can be more powerful when its details are openly shared for inspection, modification, and replication by others. The following aspects of our business will be shared for the benefit of our company, our customers, aspiring entrepreneurs, and the FarmBot community at large.

- Detailed sales and financial information including but not limited to revenues, expenditures, profits, salaries, investments, and taxes.

- Cultural, operational, and strategic insights that we determine important to our growth and success.

- We will default to transparency in all aspects of our business except when there are individual or partnership privacy concerns.

1% for the community

Each year, we shall contribute one percent (1%) of our annual net revenue towards furthering The FarmBot Project’s mission to “Grow a community that produces free and open-source hardware plans, software, data, and documentation enabling everyone to build and operate a farming machine.” Contributions shall consist of cash, products, and services that directly help to maintain and grow the community.

Be good people

We strive to do the right thing in every situation: for each other, our customers, the environment, and all of our stakeholders. We make ethics, integrity, transparency, and community the cornerstones of our business.

Capitalization

FarmBot Inc is currently wholly owned by the co-founders according to the capitalization table below. We do not have any outstanding loans and are cash flow positive.

| Founder | Type | Shares | % |

| Rory Aronson | Common | 7,650,000 | 85 |

| Rick Carlino | Common | 900,000 | 10 |

| Tim Evers | Common | 450,000 | 5 |

| Totals | 9,000,000 | 100 |

Our Product

FarmBot is a full-stack product consisting of 100% open-source hardware, software, data, documentation, and community. Each of these components is critical in delivering our value proposition: own your food. We plan to continue investing heavily in each of these areas.

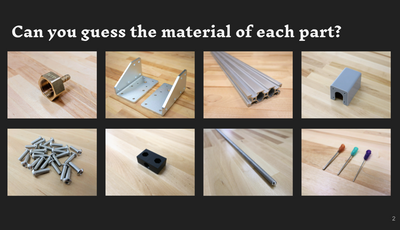

Hardware

We currently sell two FarmBot kits: a “standard” version for covering an area up to 1.5 x 3m in size, and a larger “XL” version that is twice as wide and long, tending up to 18 square meters. Pricing is based off of similar gardening products (Grove) as well as the price range of mid-level CNC machines (X-Carve) and high-end 3D printers (Taz 6). Orders are fulfilled from a warehouse in San Luis Obispo, CA.

A low end, simplified model currently dubbed “FarmBot Express” is planned for release in early 2019. It aims to feature many of the core capabilities of the current FarmBot devices, but at a lower price point.

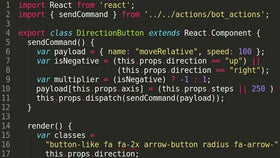

Software

FarmBot’s software is currently provided as a free service to our customers and the DIY community at my.farm.bot. While we anticipate offering a free service tier indefinitely, we plan to introduce subscription-based pro and industrial features in late 2019.

Data

FarmBot currently pulls factual crop data and crop icons from the OpenFarm.cc API. Much of this data was entered by FarmBot contractors and our community of users, while the OpenFarm codebase has been created largely by volunteers. With our Series A fundraising round, we plan to dedicate one full-time software engineer to technical development on OpenFarm and one full-time employee to begin entering crop growing information.

Documentation

Our documentation hubs include step-by-step assembly and usage instructions, ideas for modifying and extending one’s FarmBot, and technical information including a complete bill of materials. We plan to develop official FarmBot educational curriculum beginning in Q2 ’19.

Community

Since the day this project began, we’ve been building a global community of people who are passionate about changing the way we grow food. This has been a cornerstone of our success, and we plan to continue fostering collaboration between our staff, customers, the DIY community, academia, and fellow entrepreneurs. The FarmBot community forum has also served as a great tool for collecting user feedback and usage data, as well as the crowdsourcing of customer support.

Further Product Information

Since the day this project began, we’ve been building a global community of people who are passionate about changing the way we grow food. This has been a cornerstone of our success, and we plan to continue fostering collaboration between our staff, customers, the DIY community, academia, and fellow entrepreneurs. The FarmBot community forum has also served as a great tool for collecting user feedback and usage data, as well as the crowdsourcing of customer support.

Product Reception

FarmBot has been well received by our customer base and onlookers alike. Below is a sampling of what people are saying about FarmBot, how they use the technology, photos of their veggies, and testaments to the enjoyable and educational time they are having with the product.

Marketing Strategy

Our marketing strategy consists primarily of creating engaging video content in a variety of formats. These videos are used throughout our website, shared on our social media channels, sent via our email newsletter, and used in paid promotions on Facebook and Instagram. Our videos fall into three categories serving different marketing purposes for each phase of the marketing funnel:

Promotional

Our promotional videos introduce people to the FarmBot concept. Because FarmBot is a relatively new technology, these are our most important pieces of content. They convey what FarmBot is, why it is important, and how it works on a high level. These videos are directed at a very broad audience and aim to inspire and familiarize millions of people with our technology.

The promotional videos come in two lengths: the short format, meme-style versions are optimized for mobile news feeds where audiences frequently have short attention spans and watch without audio. They are designed to be shareable, quickly consumed, low cost to promote, reach a wide audience, and invite the watcher to learn more on our website.

Once on our website we present the long format, mini-documentary style version of the video. These are designed to provide a deeper overview of FarmBot, and are often paired with a call to action to “get involved” or make a purchase.

Stories

Each installment of our FarmBot Stories video series speaks directly to a specific customer segment. These videos are designed around a unique combination of “the 4 P’s” that describe a potential customer: People, Purpose, Plants, and Place. For example, our story about The Sudweeks Family (shown below) is about a young family (People) in suburban America (Place) who are using FarmBot to grow kale and other garden veggies (Plants) in order to be self sufficient (Purpose). While each of these videos may not appeal to as wide of an audience as our promotional content, they serve to show our core customer segments how FarmBot technology can fit into their lives through real-life relatable story telling.

Technical Documentation

Our technical documentation videos teach customers how to set up their FarmBot and offer a detailed look at each component and subsystem. For prospective customers, these videos inspire confidence that they too can put together a FarmBot, and serve as a more engaging way to deeply learn about our product than simply reading.

“BIG thank you for all the videos just uploaded… Building my raised bed at the moment. And while I’ve read through both the hardware and software docs once or twice since first pre-ordering last July, something about having a video explanation/demonstration of the different elements GREATLY helps with making these concepts click for me. (And I’m sure I’m not alone.) Seeing all these ‘new Youtube upload’ notifications in my inbox has genuinely renewed my excitement and confidence in moving forward.”

@romanarchitect - 1st generation FarmBot customer and community forum member

Our video content has been well received, with total consumption across platforms surpassing 150 million views. With Series A funding we plan to film additional FarmBot Stories focused on commercial and international customers, as well as usage of FarmBot Genesis XL. We will also develop promotional content for FarmBot Express to coincide with the new product’s release.

Social Media Following

Due to our viral marketing campaigns and committment to open-source, FarmBot has seen tremendous growth in its social media following. Below is a comparison of our Facebook following to other established open-source projects, competitors, and companies who sell similarly priced “maker” technologies. Not only do we have a larger following than all other pages, our community is growing at a faster rate.

Hiring a staff member to consistently share content on our social media pages will engage our followers, drive sales, and further grow our following.

Room to Improve

While our one-to-many marketing strategy has been widely successful in generating new leads, we have struggled to scale our 1-on-1 sales efforts to close every deal. With FarmBot being a more expensive product and new technology, many potential customers have technical questions and wish to speak with someone over the phone before committing to purchase. It has become apparent that this type of sales work is most important to our educational customer segement, which makes up approximately 40% of our revenue.

An additional area for us to improve is in regularly sharing smaller pieces of content via our email newsletter and social channels. Because of currently limited resources, we have been unable to post regularly and instead rely on ongoing paid advertisements to keep our following growing and engaged.

Thus, part of our growth strategy moving forward is hiring a marketing/sales representative who will manage our email newsletter, social media channels, and customer support channels.

Competitive Landscape

As a product that aims to automate all aspects of small-scale farming, FarmBot’s main competition comes in the form of consumer gardening and home automation products. The most notable competitor is Grove, though other key players such as Sprouts, Edyn, Aerogarden, Foop, Click & Grow, and Edn all aim to make growing fresh food at home smarter, easier, and more automated.

The emergence of this sector in recent years is possible because of advances in IOT technology and the continued fall in cost of sensors and microcontrollers that have led to a lower barrier to entry for new hardware companies in this space.

Many organizations have marketed similar devices to FarmBot, but they are either conceptual or serve a single, limited purpose. FarmBot differentiates itself as the gardening hardware you can buy today to automate the entire spectrum of gardening tasks rather than a small subset of tasks.

Moreover, many food production systems focus on a micro scale (Aerogarden) or a very large scale (Blue River Technologies). FarmBot currently focuses on small to medium-scale outdoor and greenhouse gardening, with plans to move into small commercial farming once the technology has matured.

Furthermore, nearly all other competitive products and services are built upon a closed-source, proprietary, walled-garden model. Feedback from our customers indicate that being committed to open-source and collaboration was a key factor in their buying decision from a technological, communal, and moral perspective. In other words, a large part of our success can be attributed to the open-source nature of our product and business, and we intend to stay committed as part of our competitive strategy.

SWOT Analysis

The following analyses are our interpretation of FarmBot’s strengths, weaknesses, opportunities, and threats (SWOT) as well as those of our competitors. We have tried to make these analyses as objective as possible and based in fact, though inevitably some statements will come down to opinion.

FarmBot’s Strengths

FarmBot’s greatest strength is that our entire system (hardware, software, and data) is 100% open-source. It is fair to say that without being open-source, Rory would not have found his co-founders nor secured initial grant funding. Further, it is highly likely that community support and sales would be lackluster if FarmBot were a proprietary system.

Moving forward, we firmly believe the future of food is open, and that the farming technologies providing true ownership to the end-eaters will be the winners in the field. Consumers will seek out hardware that is easily manufactured, modified, and repaired; software that provides complete control and customizability; data that is portable, owned by the people and users, and handled transparently; and companies that promote openness, collaboration, and treating all people and the environment with respect.

Cementing the open-source philosophy into our company bylaws legally binds us to these values, holding us accountable to our greatest strength.

In addition to being open-source, we think the following are other notable strengths of our company and technology:

- Strong leadership is at the helm of this company. To be frank, there are very few entrepreneurs who manage to take an idea to reality, build an innovative business model around it, deliver product to customers on-time, and turn a profit. Not to mention, it is even more rare to see this done with a product as complicated and unique as FarmBot.

- FarmBot is fully automated from the sowing of seeds up to harvest. The interchangeable tool mount allows the appropriate tool to be used for different tasks such as seeding, watering, weed suppression, or soil moisture monitoring. Additional tools will be created in the future to give FarmBot new abilities such as soil temperature monitoring, ammendment distribution, and depth sensing. Many other products on the market are single, limited purpose technologies.

- A variety of crops can be grown with FarmBot all in the same space at the same time, and each plant is taken care of individually based on its type and age. This allows for biologically efficient and environmentally friendly growing practices such as polycropping and crop rotation. The system has been successfully tested with over two dozen common garden vegetables.

- Our technology is scalable to suit a wide variety of use cases. Small systems are suited for research or educational purposes indoors, while medium systems are suited to outdoor growing for restaurants or families. Future larger systems may be best suited for small commercial applications. Many other automated farming systems are meant for either micro (countertop) or very large (industrial) applications, but cannot be adapted for other scales.

- A global community of devoted followers and customers has formed around our product and company due to its innovative and open-source qualities.

- The web application has been developed with a game-like UI that makes interfacing with our system intuitive and fun. Competing products have interfaces that are too technical and difficult to understand.

- Current COGS and sale prices provide us with a 75% gross margin on our hardware.

- FarmBot systems are available today, and we have delivered over 600 devices to customers around the world. Many competitors are conceptual in nature or in closed betas.

- The ROI period of owning a FarmBot is as low as 1.5 years at current sale prices. We anticipate this can be lowered to less than 1 year with the introduction of FarmBot Express and even larger FarmBots.

- Our system empowers users to lower their carbon footprint, and can be used off-grid with solar power and collected rain.

FarmBot’s Weaknesses

FarmBot’s primary weakness is its price point. Current systems cost an average of $3,000, not including the construction of supporting infrastructure such as a raised bed. While this price point is affordable compared to commercial and industrial systems (Blue River Technologies, etc), FarmBot is primarily being adopted by schools and homeowners, where other products such as Aerogarden are much lower cost. Even though FarmBot is a significantly more capable machine than lower cost systems, we cannot look past the fact that our product is simply out of the financial reach of many consumers.

However, this is the course of all new technologies — they start out more expensive and limited in functionality. Then, through economies of scale and continued investment in R&D, the product becomes less expensive and more capable over time.

It is easy to draw parallels between FarmBot and open-source 3D printing. 10 years ago, 3D printers were for hard-core early adopters, difficult to work with, and expensive. Today, they are for the mass market, easy-to-use, and relatively low cost. FarmBot technology is in the early stages of this developmental timeline.

We plan to attack this weakness in several ways:

- The introduction of FarmBot Express (a lower-cost and simplified version of FarmBot) will position our product within the financial reach of more customers.

- As we manufacture and ship more FarmBot kits, we’re seeing new efficiencies and better component prices due to economies of scale. Eventually our lowered COGS will result in a lower price point for customers.

- Scaling FarmBot to cover the maximum practical area it can will lower the cost of the product per plant or per square meter, thereby increasing its value and lowering the ROI period.

Below we have listed other weaknesses:

- FarmBot is currently a technically involved product to work with that requires committment and specific skills from the customer. By making the product easier to use, faster to set up, and more consumerized, we will eliminate this weakness.

- We cannot currently harvest with FarmBot. However, no other system within reach of non-industrial farmers can harvest either.

- Our system currently requires an active internet connection to be configured. This may be a weakness or concern for some consumers. However, those people may run our web application software on a private, local server if they wish, thereby mitigating the need for an Internet connection.

FarmBot’s Opportunities

Everybody eats, and everybody likes the idea of fresh vegetables grown right in their backyard with the practices and processes that they deem healthy. However, very few people in modern society actually commit to growing their own food because they do not have the time, knowledge, diligence, or passion for it. This is FarmBot’s largest opportunity: the millions of people and households that would grow their own food if there was an appliance-like solution that was easy to set up, fully automated, and saved them money.

There are also many other opportunities for FarmBot:

- Schools and universities currently account for 40% of our sales volume. We anticipate this market growing as robotics, programming, and STEAM based learning initiatives continue to be adopted.

- 500 million small family farms may benefit from implementing FarmBot once it has reached a low enough cost per square meter and can be easily installed, used, and maintained by undereducated people.

- Commercial ag companies may increasingly use FarmBot as a tool for R&D, trial testing, or for production.

- Restaurants, hotels, schools, and other large entities that serve food may implement farm-to-fork programs utilizing on-premise FarmBots.

- Worldwide, there are growing trends to eat organic, local, and vegetarian, all of which boost the value proposition of FarmBot to the homeowner buyer segment.

FarmBot’s Threats

As our business grows we will continue to validate and expand the market for FarmBot technology. This will de-risk competitors from entering the space and increase their potential reward. It is not a matter of if, but when we face serious direct competitors that provide FarmBot hardware kits, software as a service, or both.

While open-sourcing our product does lower the barrier for a competitor to copy us, it is important to understand that we will be copied no matter what — open-source or not. That is the reality of product development these days, and we don’t view being open-source as more than a mild enabling factor in regards to the onset of competition.

To stay ahead, we will continue innovating at a fast rate and providing the highest quality products we can. Additionally, we will build and protect business assets that are not easily replicated by competitors such as our reputation for quality hardware and service, our position as the original creators of FarmBot, our role as the stewards of the open-source community, our viral marketing campaigns, and eventual machine learning systems trained on the data from our customers. In the face of virtually unlimited competition, other open-source companies such as SparkFun, Arduino, Lulzbot, and Prusa3D are thriving with similar strategies.

Competition is not our only threat; we have identified other threats as listed below:

- Our manufacturing and supply chain is based almost entirely in China. The current political climate may cause a tariff up to 25% to be imposed on certain product categories imported into the US from China. Our product has the Harmonization Code 84329000, which is listed as a candidate category to be taxed.

- As a more expensive product, shifts in the economy may negatively impact sales.

Customer Analysis

First year sales and lead data have revealed 3 distinct customer segments:

Academic

Schools and educators have been implementing FarmBot technology as a STEM-based learning and research tool for students at the K-12 and university level. Not only has FarmBot proven to be a highly engaging project for students, it is also a burgeoning teaching tool that ties together mechanical engineering, programming, biology, agronomy, nutrition, and robotics. Furthermore, at the higher education level FarmBot can be used to conduct real-world research in a way that is more efficient and controlled than previously possible, opening up opportunities for exploring more advanced research questions. This customer group accounts for approximately 40% of our sales revenue. Read more about this customer segment and watch our related FarmBot Stories on our educational landing page.

Home Consumer

Homeowners and DIY enthusiasts have always been the core demographic to which FarmBot was designed for. Due to the large audience that our promotional videos has reached, FarmBot is quickly becoming a commonly understood name, topic, and concept amongst this demographic. Members of the maker movement as well as traditional American families have been integrating FarmBot technology into their lives and are a core driver of activity in the community forum. This customer group accounts for approximately 40% of our sales revenue.

Commercial

Agricultural and research organizations such as Bayer and NASA are piloting FarmBot technology for use in non-home environments such as industrial ag production and hyper-controlled remote growing environments. This customer group accounts for approximately 20% of our sales revenue. Read more about this customer segment on our commercial landing page.

The Founders

Rory Aronson

Rory Aronson is the founder of The FarmBot Project and the CEO of FarmBot, Inc.

After graduating with a Bachelor of Science in Mechanical Engineering at California Polytechnic State University, San Luis Obispo in 2013, Rory began working on FarmBot in his spare time. In early 2014 Rory was named a Shuttleworth Foundation Fellow and received a $125,000 philanthropic grant to continue work on FarmBot.

Over the next three years, Rory advanced FarmBot’s hardware while company co-founders Rick and Tim developed the initial implementations of the FarmBot software stack.

In April of 2016 the co-founding team incorporated FarmBot, Inc. as a California Benefit Corporation, ensuring that the open-source roots of the company were integrated into the corporation’s legal purpose.

In July of 2016 the company debuted its first product: FarmBot Genesis. Rory has since been growing and leading the team while also developing company strategy, high-level system architecture, marketing material, the manufacturing and supply chains, and continuing to improve the hardware design.

Rory is also the CEO of OpenFarm, Inc., a 501(c)3 nonprofit that was spun out of FarmBot to become a standalone application and community that aims to be the “Wikipedia of farming and gardening”. OpenFarm’s API is used by the FarmBot virtual farm designer. OpenFarm has been self-funded via a successful Kickstarter campaign executed by Rory in September of 2013.

Rory is also a co-founder and the COO of the SLO MakerSpace — a community workshop and craft center in San Luis Obispo, CA. FarmBot currently rents approximately 300 square feet within the SLO MakerSpace for R&D, and utilizes the space and equipment for light manufacturing and prototyping.

Rory has spoken at length about FarmBot at various ag-industry, technology, and academic venues including TEDxUCLA in Los Angeles, CA in 2014; Produce Marketing Association’s Tech Talks in Charlotte, NC in 2015; the Hackaday Superconference in San Francisco, CA in 2015; the Institute for Advanced Learning and Research in Danville, VA in 2017; and Viva Technology in Paris, France in 2017.

Rick Carlino

Rick Carlino is the lead software developer and a co-founding member of FarmBot, Inc.

Rick’s role at FarmBot began in 2013 after reading the original FarmBot white paper. After reading the whitepaper, Rick reached out to Rory to find ways to help FarmBot meet its software goals.

Since 2013, Rick has helped move the project forward by building and maintaining the FarmBot software platform. He also built much of the initial code base for OpenFarm during the initial crowdfunding campaign. Rick specializes in database systems, Linux and Open Source software development.

Rick has built a variety of software projects during his 6 year career including projects for medical payment processing, textile manufacturing, hospitality management services, non-profits, the military, and a list of Fortune 500 consulting clients too numerous to name. He has extensive hands-on experience managing databases, large codebases, telecommunications systems, message queueing systems and security-critical applications.

Rick’s interest in software development began at an early age as a personal interest and later as a professional path. Rick studied Interdisciplinary Studies at Arizona State University with a business management and Korean language focus.

Rick’s interest in technology and entrepreneurship has also led to the founding of Fox.Build — a makerspace and collaborative work area for technologists and entrepreneurs in the Chicago area.

Tim Evers

Tim Evers is the lead firmware developer and a co-founding member of FarmBot, Inc.

Tim’s role at FarmBot began in 2013 after reading the original FarmBot white paper and connecting with Rory to help develop the device’s firmware.

Since 2013, Tim has continued to develop new features for the firmware, including the world’s first production implementation of closed-loop feedback control for an Arduino-controlled CNC machine in FarmBot’s class.

Tim’s interests lie at the intersection of technology, sustainable development, and self sufficiency, leading him to have also played a critical role in the shaping of the company’s open-source culture and values.

Outside of his role at FarmBot, Tim is a senior software developer in the European factory automation field.

Our Team

Since our initial crowdfunding campaign in 2016, we have been slowly expanding our team as revenues allow. Our payroll currently consists of four salaried employees with benefits and five contractors. The photo below is from our first company retreat at the NASA Kennedy Space Center in Florida, where we participated in a brainstorming event for innovative open-source approaches to food production. Watch the story.

Financial Plan

All revenues to date originate from the sale of complete FarmBot hardware kits, partial kits, and individual parts. Sales are generated via social media advertising and internet video marketing campaigns as discussed above.

Planned revenue streams for the future include premium based software addons, subscription based software as a service, next generation FarmBot hardware devices, and further components for upgrading and expanding one’s system.

FarmBot has been completely self funded and has met all financial obligations to date. Revenues are expected to grow as additional product offerings are added and full-time marketing staff are hired.

As a mission-driven and socially-minded company, we’re focused on the triple bottom line: People, Planet, and Profit. Our goals of treating people right, making the world a better place, and running a great business must always be aligned. We see investment in our company as an investment in humanity, and seek to find interested parties who align with this vision.

Series A Fundraising

FarmBot is currently a financially sustainable and growing organization. Seeking Series A investment is about increasing the speed at which we can expand our team, improve our product, and bring FarmBot technology to more people. We are not seeking investment out of necessity.

Over the next year and a half, we plan to spend an additional $3M to accelerate our business to the next level, with the goal of becoming financially sustainable again at our new scale by Q4 ’19. The table below shows how we will invest this captial.

| Description | Est. Cost |

| Streamline warehouse operations. Hire part-time sales manager to handle shipments, maintain the online shop, shipment related tasks, and customer service. Frees technical and founding members to focus on core technology and stategy. | $60,000 |

| Hire part-time staff to manage financial and HR matters. Frees founding members to focus on core mission. | $60,000 |

| Hire marketing staff member to manage customer support, newsletters, social media. | $80,000 |

| Promote part-time OpenFarm data entry staff to full-time to allow for development of “growing guides” in addition to crop entry activity. | $80,000 |

| Create 3-4 additional “FarmBot Stories” focused on international and commercial usage of FarmBot and the Genesis XL device. | $60,000 |

| Write official FarmBot educational curriculum in partnership with institutions. Hire full-time education coordinator. | $100,000 |

| Fund manufacture of v1.5 kits, increase inventory. | $500,000 |

| Bring “FarmBot Express” to market, adding a full-time hardware engineer and a supply chain manager to scale production while maintaining quality and cost. | $300,000 |

| Expand software team by 5-10 full-time developers and a project manager over a one year period. Provide full-time developer to OpenFarm project. | $1,000,000 |

| Increased operating expenses due to team expansion (office space, travel, software services, etc..) | $250,000 |

Exit Strategy

Our exit strategy is not one of the typical technology startup. We are not seeking to go down a path of never-ending hypergrowth in blind pursuit of the next fundraising round or a quick acquisition. We are not willing to compromise on our values for the sake of profit. And we are not open to focusing on short-term gains at the expense of the long-term viability of our business.

Instead, we are most excited about building a thriving, sustainable organization that allows us to bring FarmBot technology to the world for years to come. When the time is right, healthy profit sharing is our preferred method of providing a return to our shareholders.

Employee Compensation Policy

FarmBot has adopted the following public pay formula for all paid members of the team.

Hourly Rate = Role Base Rate * Seniority Multiplier * Experience Multiplier + Location Adjustment

Salary = Hourly Rate * 2,000

These are the roles and corresponding base rates we currently have defined:

- C-Level Executive = $40/hour

- Lead Software Developer = $37/hour

- Lead Hardware Engineer = $37/hour

- Software Developer = $33/hour

- Hardware Engineer = $33/hour

The seniority multiplier is 1 (no effect) for members consistently with us for under 1 year, 1.1 for those with us for over 1 year, 1.2 for over two years, and 1.3 for over three years. The experience multiplier is subjective and can range from 1 to 1.3 in 0.1 increments. The Location Adjustment is used to account for the cost of living in the employee’s area. It is calculated using the Consumer Price Index for the area based on the http://numbeo.com database. It is +$0 for CPI 0-32, +$1 for CPI 33-65, +$2 for CPI 66-98, and +$3 for CPI 99-130.

The company does not currently offer employee stock compensation or options, though we plan to establish options during the Series A round.

Operations Plan

Our main goals for this fundraising round are growth and feature development. We will add new employees to fuel sales and marketing campaigns, add a new product to our product line, and continue our development of software and data-based features such as weed detection, automation, and decision support for truly automated food production. Specific milestones include:

- Ship the first production batch of Genesis XL devices (Q2 ‘18)

- Release an initial software Decision Support System (Q4 ‘18)

- Bring FarmBot Express to market (Q4 ‘18)

- Announce premium software features (Q1 ‘19)

We anticipate hiring a mix of distributed developers across the states as well as personnel located in the Central Coast region of California. We have already secured a 4,000 square foot combined office space and warehouse in San Luis Obispo to accomodate new and existing staff, R&D, and inventory up to 3,000 kits. We plan to move into the new space in July of 2018. Through the hiring of additional staff, our current technical team members will be free to focus on core developments, while our management team can focus on strategy, growth, and scaling the team.

Additionally, we plan to continue sponsoring and mentoring student teams throughout the US who are committed to advancing FarmBot with us. To date, we have worked closely with over 50 students across mechanicical engineering, computer science, electrical engineering, marketing, business, and manufacturing engineering. These partnerships have provided inexpensive R&D resources and creative energy to our team, and created a pool of potential hiring candidates.

Manufacturing

Nearly all of the FarmBot hardware components are manufactured and sourced in the Shenzhen/Guangzhou region of China. We plan to continue manufacturing in this region as we have developed a close relationship with a contract manufacturer and R&D house, LDO Motors. With LDO and its partners, we have invested in significant tooling such as stamps, injection molds, and extrusion dies that allow us to manufacturing high quality parts for low cost, at scale.

Through several visits, we have seen first-hand the facilities and processes used to manufcture our parts, and met some of the many other workers, engineers, and sub-contractors that LDO partners with. We plan to continue making regular visits for quality assurance purposes, to build rapport, and to jointly discuss manufacturing strategy.

Milestones Passed

2011 – 2015

April, 2011 — Rory had the idea for FarmBot while taking an organic agriculture class at Cal Poly, San Luis Obispo.

June, 2013 — Rory graduated from Cal Poly with a BS in Mechnical Engineering and began writing The FarmBot Whitepaper in his spare time.

September, 2013 — Rory published The FarmBot Whitepaper online as a free and open-source idea and sent out a call for help to further develop the idea.

October, 2013 — Rick Carlino and Tim Evers offer to help with web application and firmware development respectively.

January, 2014 — Rory is awarded a Shuttleworth Foundation Fellowship in the amount of $125,000 to continue development of FarmBot for 1 year. Over the next year and half, the team develops several iterations of FarmBot hardware and software, bringing the idea from concept to reality.

2016

April, 2016 — Rory, Rick, and Tim incorporate FarmBot Inc. as a California Benefit Corporation, cementing the project’s open-source roots into the company bylaws.

July, 2016 — Launched a crowdfunding campaign for FarmBot Genesis – Humanity’s First Open-Source CNC Farming Machine. During July, 275 pre-orders were accepted resulting in over $800k in revenue.

October, 2016 — The FarmBot hardware team travels to Shenzhen, China to meet with part suppliers and manufacturers. Production of 350 v1.2 FarmBot Genesis kits begins.

2017

January, 2017 — Sold out of v1.2 kits and began accepting v1.3 pre-orders.

February, 2017 — Began shipping v1.2 kits to customers all over the world from our San Luis Obispo warehouse.

April, 2017 — Began production of 300 v1.3 kits.

July, 2017 — Held our first company retreat at the NASA Kennedy Space Center for a brainstorming event on innovative open-source approaches to food production.

October, 2017 — Open-sourced the v1.3 documentation and began shipping v1.3 kits to customers.

December, 2017 — Debuted our second product: FarmBot Genesis XL, and began accepting pre-orders for v1.4 hardware. With the introduction of Genesis XL, monhtly revenue is doubled, surpassing $100k.

2018

February, 2018 – Opened our full online shop to offer partial kits and individual parts in addition to full FarmBot kits.

March, 2018 — Began manufacturing 500 v1.4 devices (300 standard size, 200 XL).

April, 2018 — Surpassed 100k Facebook followers.

July, 2018 — Moved into a 4,000 square foot warehouse and office space in San Luis Obispo.

August, 2018 — Launched a new website and online shop powered by Shopify. Open-sourced the v1.4 documentation and began shipping v1.4 kits to customers.

The Road Ahead

Concluding The FarmBot Whitepaper in 2013, Rory laid out several milestones to define short-term success:

- Demonstrate a functioning minimum viable product to prove the technology’s feasibility.

- Make available the hardware plans, software source code, and purchasable FarmBot kits for others to easily get involved.

- Foster a community of early adopters and contributors with the goal of self-sustaining organic project growth.

In the four years since publishing the whitepaper, we can confidently say we have passed these short-term milestones. Now we look down the road to see what’s next.

Defining Long Term Success

We firmly believe FarmBot will dramatically shift the way humanity produces food at small and medium scales. By transferring power back to the people and growing food in an automated and efficient way, we’re certain that FarmBot is an important step towards feeding the world and taking care of our planet in the 21st century.

Moving forward, long term success is to see FarmBot as a widely adopted appliance in homes, schools, and industry. To achieve this, we have defined two new milestones:

1. Improve the entire product so everyone is empowered and excited to participate in the FarmBot movement. This includes at least the following:

Hardware — Lower the cost of the hardware; increase reliability and performance; add new tools, sensors, and capabilties; make kits that are easier to assemble and maintenance; offer additional FarmBot sizes and form factors to suit a variety of environments and use cases.

Software — Abstract low-level functions so users can focus on high-level tasks such as designing the farm; support decision making for truly smart and hands-off operation.

Data — Build a robust dataset to enable automated growing of a large variety of crops in common environments without prerequisite user knowledge.

Documentation — Expand our documentation to cover specific use cases such as FarmBot in the classroom, as a research instrument, or as high output production equipment.

Community — Further engage the community in data sharing, research and development, and advocacy.

2. Move beyond the early adopter market and bring FarmBot to the mass market. This will require scaling our manufacturing and supply chains and other business operations to support shipping millions of devices per year instead of hundreds.

Closing Thoughts

This document illustrates what we have accomplished over the last four years of working on FarmBot, and more importantly, where we would like to go next. We hope you share our vision for the future of food, and we look forward to speaking with you. Thank you.

Please direct inquiries to rory@farmbot.io.

First published January 29, 2018.

Last updated April 11, 2018.